Vanquish Products Ripper - Prototype

background

This project was born out of my plan to build a new chassis for myself in the spring of 2017. My plan was to build the chassis out of steel as I had done many times before. However in the early stages of sketching, Jim (@RipperMachinist) suggested that we change the course of the project and that we machine EVERYTHING. We decided to combine the ideas of a machined cage and the concept of a machined body panel set that Jim was going to make for the Axial Yeti. We decided to shoot for a deadline of Axialfest 2017, which gave us only 2-3 months to finish the project. To be Axialfest legal in 2017, we needed to retain the SCX10 chassis, so that was where the design had to start from.

Prototyping

The prototyping phase was compressed and not many changes were able to happen during this time as the schedule just didn’t allow it. We 3D printed the chassis in sections on our Form 2 SLA style 3D printer. We also printed half of the hood and the grill to see how everything would line up. Seeing the parts manifest themselves in the physical world made our excitement grow exponentially. I finalized the design of the cage and body, the new Currie F9 axles for the SCX10-II would also be debuting with the unveiling of the Ripper. This added another complexity to our schedule since we had to complete all the things that go along with the release of a new product along side our extensive custom project.

MACHINING

The programming and fixturing was the most intensive portion of the project. It was planned to machine the chassis out of three total blocks of material: left chassis side, right chassis side and then the three center chassis pieces would be machined from one block. Each of the three chassis blocks would start out at around 20lbs. The body panels would come from three additional blocks: a 9lb hood block, both side panels would come from one 17lb block, and the grills are made 4 at a time from a 10-15lb block. The total material used to create each Ripper is nearly 100lbs and takes 30+ hours from start to finish. We stayed late nights in hot conditions to keep our finger on the button of the machine during the proofing of the programs. The finished thickness of the body panels is only 0.025”, which you almost need to see in your hand to truly appreciate.

Hood blank before machining

After the first operation is complete for the hood

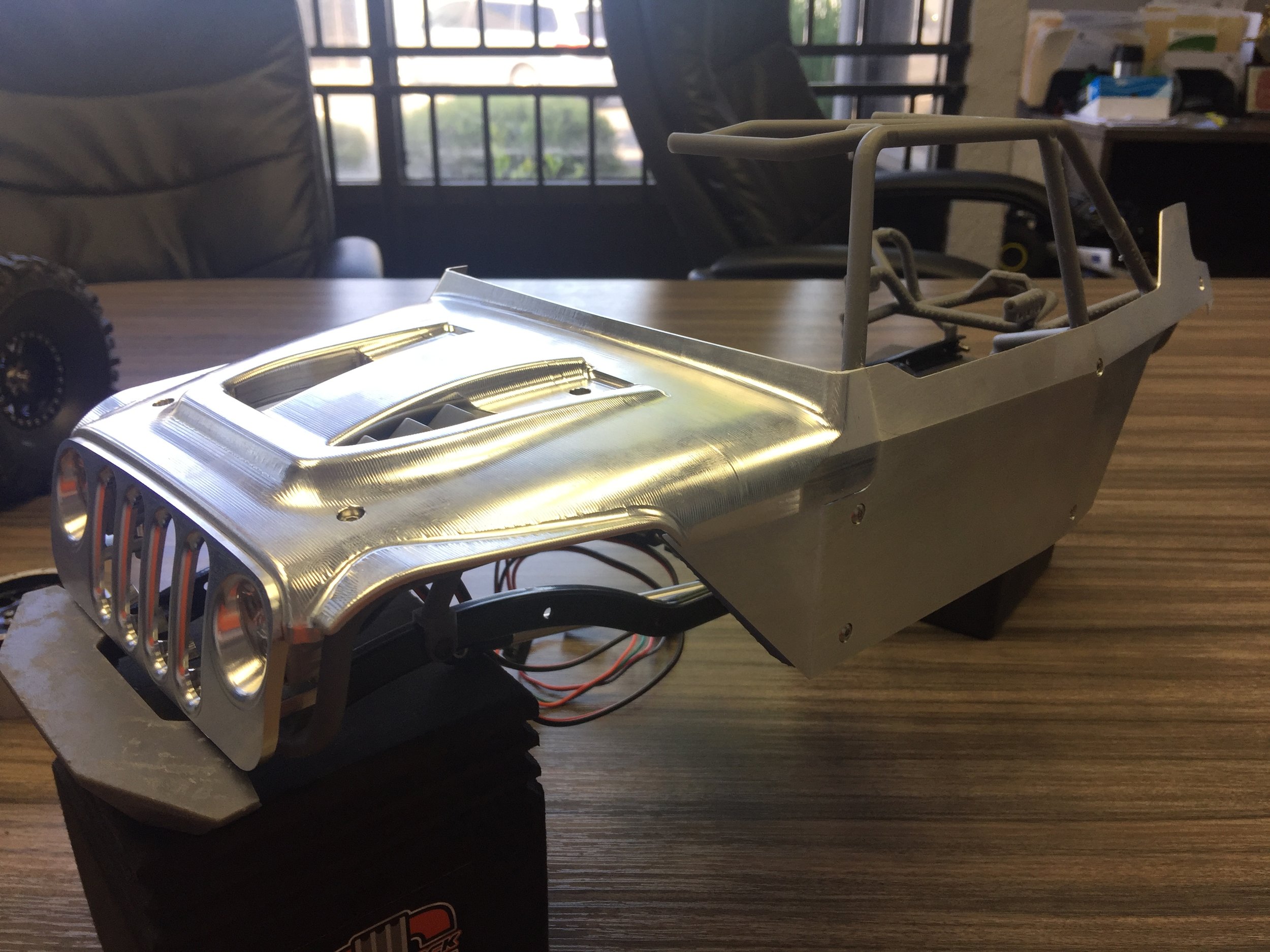

Hood and grill resting on the 3D printed test chassis

Driver side panel sitting in place on the 3D printed chassis

Chassis side panels finished

Under the hood, grill and chassis mounting

When the material was ordered for these trucks, we had enough to build 9 trucks. We never planned to build more of these when we started on this project, but that all changed a couple of months after the completion. The original prototypes belong to the following people:

#01 - @RipperMachinist

#02 - Harley Designs

#03 - Casey Currie

#04 - Currie Enterprises

#05 - David Castillo (formely w/Currie Enterprises)

#06 - KMC Wheels

#07 - Taylor Anderson (Founder of Rigid Industries)

#08 - Bob Tarvin (VP shop friend)

#09 - scrapped in machining

Build Breakdown:

Current Status (pictures shown during multiple variations)

Base Vehicle: Axial Racing SCX10-II

Chassis: Vanquish Products Ripper Chassis, Ripper Body Panels, Vanquish Products VS4-10 Skid plate, rear cross brace, rear chassis plug, Vanquish Products Ripper Front Bumper

Wheels: Vanquish Products Method 105 with 350 SLW hubs

Tires: Vanquish Products VXT

Motor: Tekin ROC412 2300KV

ESC: Castle Creations Mamba X

Servo: Futaba S9177SV

Lights: Vanquish Products Q-Series Headlights, Vanquish Products 4” Rigid LED light bar with red LED’s in rear, MORE LLC 1” Blue LED bar on front bumper in Vanquish Products Rigid Housing, HeyOK 3 position lighting controller with direct battery lead for increased amperage and 3s power feed.

Transmission: Vanquish Products aluminum case, Incision machined transmission gears, Vanquish Products Gear Guard and Motor Plate, Vanquish Products Hurtz Dig, Incision Slipper Eliminator, Vanquish Products Idler Gear Pin

Front Axle: Vanquish Products Currie F9 housing, F9 Servo on axle mount, Vanquish Products SCX10-II Knuckles, Vanquish Products AR44 6-bolt gears, Vanquish Products Spool, Incision VDI Axle Shafts, Fast Eddy Bearings

Rear Axle: Vanquish Products Currie F9 housing, Vanquish Products AR44 6-bolt gears, Vanquish Products SCX10-II Spool, Vanquish Products SCX10-II chromoly axle shafts, Fast Eddy Bearings

Suspension: Ripper Link Set, Incision 90mm Scale Shocks, 60wt Shock Oil

Radio: Futaba 4PV

Receiver: Futaba 2106GF

Batteries: Gens Ace 4000mah 3s Lipo